Basic HTML Version

สาขางานช่

างฝี

มื

อดั้

งเดิ

ม

มรดกภู

มิ

ปั

ญญาทางวั

ฒนธรรม

52

T

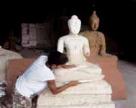

he model making and casting of the Buddha

statue

are classified in Thailand’s Chang Sip Mu

(Ten art and craft categories). It belongs to the casting

category, and it also involves model making--which

is classified in the sculpture category. The two processes

are related because a model or a sculpture must be

made before the casting process can begin.

The Thai traditional methods of model making and

lost-wax casting of the Buddha statue are as follows:

Model making

- The model making starts from

making the core of the model, which is made of sand

and clay mixture. The next step is to make V-shaped

channels - the main one with its branches - for pouring

in the molten metal to replace the wax. A layer of

Din Mom or clay mix - a mixture of ash, clay, and

water - is then applied to coat the core and

strengthen it. This is followed by the Tha Thueak

process whereby a coat of vi scous l iquid -

amixture of beeswax

and thick rubber oil

is applied. Finally,

wax is applied in the

Khao Khi Phueng or

wax coat process,

wh i c h i n v o l v e s

forming the wax

coat that will serve

as the original model and will look exactly like

the desired cast. This wax sculpture is modeled in

fine details and chased. It will become the mold cavity

to be filled with the molten metal.

Moldmaking

-Theprocessbeginswiththeapplication

of Din Nuan (clay mixed with cow dung and water)

on the wax figure. Three coats are required and

each time the coat must be left to dry thoroughly

before applying the next coat. Metal pins are

then inserted through to the core model in order

to stabilize the mold cavity. Vents are attached

for wax removal. Din On - Din Nuan mixed with

fine-grained sand and water - is applied to coat the

figure which has been fixed with pins and vents for

wax to pour out. This forms the first layer, which is

The Buddha Statue Model Making and Casting

coated over with a slightly thicker layer of Din Kae -

a mixture of clay, fine grained sand and water

to form the second layer of coat. Metal wires

are then strapped in a mesh-l ike fashion to

protect the mold from the pressure that will

build up inside when the mold is heated, which

might crack and break the mold. The second layer

of Din Kae is

then appl ied

to cover the

wire strapping

and the mold

is left to dry for

four to seven

days. Then Pak

Chok (pouring cups or pouring basins) and Ru Phut

(vents for gas generated during the pour) are made.

LostWaxor Investment Casting

- Theprocess begins

with Lom Hun or moving the mold to the area where

metal pouring will take place and followed by Khuen

Thon or flipping the mold. Scaffolding is constructed

and a channel for receiving the melting wax is

fixed in place. The mold is then heated to remove

the wax. The metal is melted in a crucible and poured

into the mold cavity.

When t he me t a l

c oo l s down a nd

solidifies, the mold

i s des t r oyed and

the wi re strapping

i s r emoved . The

metal figure is chased

and blackened or

applied with lacquer coat and gilded.

The Thai traditional method of model making

and casting of the Buddha statue reflects the folk

know-how in appropriately selecting the local

materials and the unique method of casting hollow

sculptures with fine, thin shell. The Buddha statue

model making and casting is therefore considered

a hi ghly valued rel i g ious ar t and craf t and

has contributed to perpetuation of Buddhism

in Thailand.